Second in the Helping Dad Series

Mom and Dad were married 20 years before they began to live on and work their own farm. One reason for the length of time was that they wanted a dairy farm. Starting one from scratch takes lots of money in equipment, cattle, and buildings. It was the primary source of our income and also our expenses.

My parents didn’t care to buy things with credit; they never had a credit card. They saved all those years to own their own farm. They still needed loans to make it happen. They got a contractor to build the house. The barns and outbuildings they built themselves or were already part of the farm.

Dad maintained a Grade A certificate for the dairy operation. This allowed him to sell his milk to a factory that bottled it for milk, not cheese or ice cream. This type of operation provided the highest price. You get the idea.

Grade A dairy farms got inspected regularly and without notice. The officials looked for cleanliness first and foremost. For example, the area where the cows were milked had to be reasonably clean; the interior and exterior walls had to be “whitewashed” with a paint and lime solution. The outside area around the milk shed and milk storage had to be trimmed so that weeds and grass did not grow too tall. The milkers and buckets were sanitized after every milking. Each cow’s udder had to be washed just before she was milked. There were other regulations; these are the ones I remember.

The milk had to be stored in what we called the milk tank in the milk room. We weren’t much for creative names for things, I suppose. The milk room had to be separated from the cows’ area. That makes sense to keep the milk as germ-free as possible.

The milk tank stood in the middle of the room. It was large, stainless steel, and double-walled. Chilled water in the walls circulated to cool the milk quickly. It also had an agitator that swirled the milk around for chilling and stirring the cream into the milk. It held 1,000 gallons. That would be very small by today’s standards. The milk tank chilled the milk to a colder temperature than a refrigerator would. I have to guess, but that seems like another way to keep germs at bay. A tanker truck came every third day to pump the milk from the tank and deliver it to the processing facility.

Helping Dad in the barn including getting the milk from the cows to the milk tank. The buckets we used to carry milk were tall and narrow, about 18 inches tall and 7 inches across, made of stainless steel. These buckets were strong and sturdy to withstand use in the barn, and easy to clean. They held about 3 gallons of milk and weighed about 6 pounds when empty. When completely full of milk, the total weight was about 30 pounds. Typically a bucket would be two-thirds full and weighed a little over 20 pounds.

Round portholes in the top of the milk tank let you empty the buckets into the milk tank without opening the entire top of the tank. You poured into a big funnel into the porthole so you didn’t spill any milk. The funnel fit snugly in the porthole. It wouldn’t move much while you poured. The funnel could hold about half of the full bucket of milk, making pouring the heavy bucket a little easier. Inside the funnel was a place for a filter. The filter was to remove debris from the milk that may have fallen in the open top bucket in the short trip from the milk shed to the tank.

I needed to lift the bucket from the floor to a height that was about to my shoulders to pour out the milk. It was 20 pounds a lift and I had to do it without spilling. Forty cows to be milked meant forty buckets of milk.

When I first started helping Dad in the barn, it didn’t take long for me to decide that I was too short for the pouring part of the job. I struggled for several milkings, knowing that saying I couldn’t do a job without trying was wasting my breath. During that first week, Dad asked a couple of questions about how long it took me to get milk in the tank.

Dad was used to having my brother in the barn, seven years older than me. I was about 11 when I started helping. My brother had graduated high school and had a job. It was my turn, as it had been his; it was my older sister’s job before that. Helping in the dairy barn would fall to my younger sister too.

My child’s brain said that I would not have to lift the buckets after telling Dad I was too short. What could he or I do about it? I could just carry them to the milk room. Dad could pour them into the funnel. For a day or two, he did.

Dad was pleased with himself one afternoon soon after I admitted that I was too short to put milk into the tank. He had a surprise for me. Was I ever surprised!

A wooden step stool sat on the floor in front of the milk tank. Dad built it for me. It was just the right height and width for me to pour milk out of the bucket and into the funnel. He had a solution, just not the one I thought. I used the step stool the rest of the time I helped Dad in the dairy barn.

Have you ever tried to describe something you are familiar with but have trouble putting it into words? That is me and the dairy operation. I have many memories, but I have difficulty translating them into sentences and paragraphs. The following section describes how we went about milking cows in Dad’s milk shed.

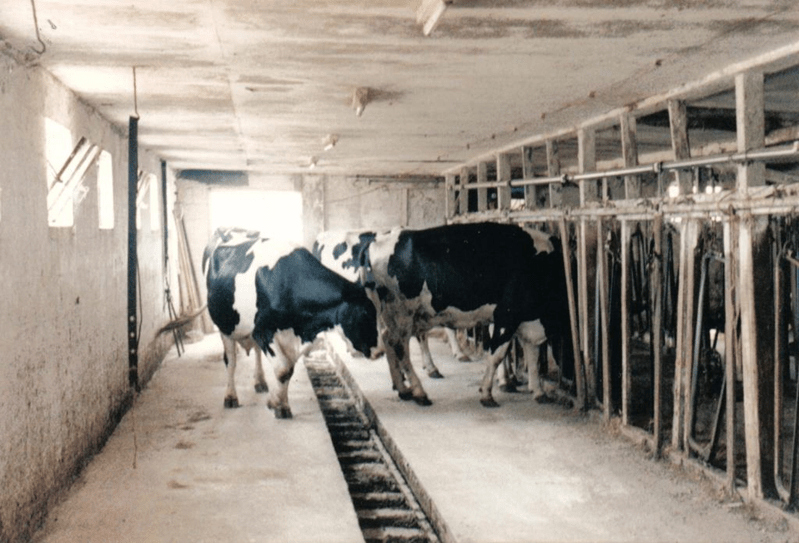

The milk shed was about 40 feet wide and 75 feet long. It had concrete block walls and a poured concrete floor, There were two rows of cows when the shed was full and the cows faced each other. The cows stood with their heads in stanchions, 20 cows on each side. Stanchions in a dairy barn are long metal rectangles hinged at the bottom with a latch on the top. When opened, a cow can put her head through. She cannot back out when the stanchion is latched. The stanchions hung from significantly large chain links at the top and other links were at the bottom. The chains were attached to heavy wooden timbers above and below the stanchions. . Another length of timber ran along the ceiling. All three stretches of timber went the length of the stanchioned area. Posts from the ceiling to the floor attached to the three horizontal timbers to anchor the stanchions. The stanchions stood about five and a half feet tall, over my head now as an adult. They looked enormous to me as an adolescent.

The stanchions, chain links and timbers were to keep the cows in place and make milking them safer. The set up had to be sturdy because cows are large, strong animals. Adult Holstein cows weigh up to 1,500 pounds and can be 5 feet tall at the shoulder. In stanchions, the cows couldn’t get aggressive over the feed or butt and kick each other because of bad attitudes. It was safer for us with the cows confined, but you could still get hurt. Dad had a few cows over the years that kicked most of the time when you tried to put the milker on. A cow could step on your foot and you could be squeezed between them if adjacent cows moved in toward you. You could suffer the indignity of having the cow swipe her dirty tail across your face. Metal piping with nozzles was attached above the stanchions, one nozzle per stanchion. The pipe attached to a vacuum pump in the milk room. The pump provided suction for the milking apparatus.

The floor had a channel about 6 feet from the outer walls. It was about two feet across and a foot deep. This channel ran all the way around the milk shed. This was the manure trough and was positioned to catch most of the waste generated by 40 cows during milking. The quantity was more than you might expect. Dad had a system in the trough that carried the manure outside to the manure pile. It consisted of a geared chain with paddles that was pulled along by an electric motor. Sometimes simple is the best way.

The space between the stanchions and manure trough was occupied by the cows. It was 5 or 6 feet wide. Each row of cows had a feeding trough that ran the length of the stanchions. The 6-inch deep troughs were where the cows got their scoops of feed sweetened with molasses and fortified with vitamins and minerals. Milking cows use a lot of calories to produce, so the feed supplements the grass of the pastures. A walkway was in the center of the milk shed, between the feeding troughs. We used that walkway to close the stanchion latches and scoop feed into the feeding troughs.

The milking process included many steps, some I have already mentioned. The cows must be gathered into the barn lot. Dad used a call to alert them that could be heard all over the farm. It was sort of like “HEEWW-WEEE .”The pitch was lower-toned at the beginning and ended higher, but not high-pitched. Dad used a lot of air to make it heard as far as it was. No one else in the family could imitate it.

Most of the cows came on in without being called. The milking cows had full udders, they wanted relief, and they wanted the sweet feed that only the milking cows got to eat. The whole herd needed to come in for Dad to see them. A cow can get into trouble in the pasture, a pregnant cow might give birth sooner than expected, or an adventurous heifer might find a hole in the fence.

After they all have gathered and Dad is satisfied that none are missing, he opens the door from the milk shed to the barn lot. A cow herd has a pecking order, the top cow always walks at the head of the herd, and she always goes into the barn first.

Cows are creatures of habit, so if a cow is trained to go to a certain stanchion, she will go to that one every time she comes into the barn. Heifers are taught which stanchion to use before she has their first calf and becomes a milking cow. This takes time and patience, and in Dad’s barn, the help of our cattle dog and sometimes one of us kids. The heifer is directed into a stanchion where feed is ready. She is used to people, but not being in the barn, so she will try to escape. We gradually direct her in by closing the space, not too fast, or someone, including the heifer, could get hurt. It may take a few times for her to get the idea.

Dad started milking soon after the cows came in and settled down to eat. He began on the same side, the same end of the cows and the same cow. He reached for the bucket with the washing solution, took the rag without wringing it out, and washed the cow’s udder with it. Next Dad brought over the milking machine. A long vacuum hose came out of the top of the machine, Dad attached the long hose to a nozzle above the stanchion. The milking machine then had suction. Dad took a long leather or cloth strap with a long curved metal bar on one end. The strap went over the cow’s back and the bar hung under the cow, attached with a hook on the bar and large grommets in the strap. The milking machine had a hook on top that fit on the metal bar to hang the machine under the cow.

The milking machine was simple. It was about 16 inches across. The opening at the top had a cover with 4 short hoses. The hoses were attached to metal tubes that were about 6 inches long. the tubes had soft rubber inserts. The tubes, called teat cups, were placed on the cow’s teats. Intermittent suction constricted the rubber insert and then loosened it. In this way, milk was drawn out of the udder and into the bowl of the milker. The bowl portion held about 2 gallons, the average amount a cow gave per milking.

You could tell by the sound when the milking machine had all the milk from a cow. The steady whoosh, whoosh sound of the vacuum pump was punctuated by a sucking sound. The sound was because the cow’s full and tight udder and teats were now looser and smaller. The teats no longer filled the teat cups, so the suction pulled air in around the teat. That was the signal to take the miking machine off the bar under the cow and take the strap from her back.

The machine was opened and the milk was poured into a large stainless steel bucket like I described early in this story. The bucket got carried to the milk room and the milk was poured into the milk tank. The cow was released from her stanchion soon after she was finished with her milking. She would go quickly back out the barn lot door without having to be guided. You do this with every cow. When all the cows are milked, you take the stainless steel buckets, funnels, and milking machines, to the milk room. The regulations for Grade A milk included having a hot water heater and 2 tubs for washing the equipment. Dad milked cows almost every day, twice a day for over 50 years.

Milk is less expensive now than when Dad was milking cows, so the dairy gets less per gallon of milk. This comparison would be after converting dollars from then to the value now. Stanchion milk barns like Dad had are not used any longer, either. Milk parlors are constructed differently now; the layout allows larger herds to be milked more quickly. The days are gone when Dad knew each cow and knew when that cow was ready to have a calf or was acting sickly. The large corporate farms have teams of employees who work in shifts. Cows are usually kept confined in lots now, not let out to graze in pastures. Several changes in our society have created a decrease in the number of family farms. In my opinion, the changes came from- the lower price and higher demand for dairy products; the higher prices of land and equipment that prevent potential family dairys from getting started; the decrease in farmland due to development; and the lack of interest that many young people have for taking over the farms that they grew up on.

I was one of those young people who chose to leave, go to college and have a scientifically based career. I saw the sacrifices needed to make a living in farming. I did not want to be tied to a dairy, milking twice a day, every day, unable to go out to dinner, catch an evening concert, or go on a trip overnight. My brother and younger sister also decided to make a living doing something besides farming. My older sister’s heart was always on the farm. She and her husband farmed for several years for other people like Mom and Dad. They bought a farm but sold it when the cost of keeping it passed the income it brought in during a real estate pricing bubble. She loves horses, and so did her spouse. They found a few acres, built their house themselves, and kept horses until they could no longer care for them. My older sister, in her mid 70’s now, is still more comfortable outdoors in the sun than doing anything in the house.